OEM/ODM Factory Zinc Plating Polyethyleneimine G-35 Sp-200 Sp-1050 P-1050 P-1000 Sp-018 CAS 68130-97-2

Quality First,and Customer Supreme is our guideline to provide the best service to our customers.Nowadays, we are trying our best to become one of the best exporters in our field to meet customers more need for OEM/ODM Factory Zinc Plating Polyethyleneimine G-35 Sp-200 Sp-1050 P-1050 P-1000 Sp-018 CAS 68130-97-2, We adhere to the tenet of “Services of Standardization, to Meet Customers’ Demands”.

Quality First,and Customer Supreme is our guideline to provide the best service to our customers.Nowadays, we are trying our best to become one of the best exporters in our field to meet customers more need for China Polyethyleneimine and Zinc Plating Polyethyleneimine, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our products and solutions. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best in your case always.

This product is a colorless or yellowish high viscous liquid. Soluble in water, ethanol, hygroscopic, insoluble in benzene and acetone. Precipitation will occur when it meets sulfuric acid with a pH value lower than 2.4. The aqueous solution is positively charged, and the addition of formaldehyde produces condensation. It is used as the wet strength agent of non sized breathing paper, and the retention agent and beating agent in the process of papermaking can reduce the beating degree of pulp. Improve the dewatering capacity of paper. The dryness of the paper is increased by 1% – 4%. The production capacity is increased by 5% – 20%.

| Purity Optional | ||||

| MW 600 | MW 1200 | MW 1800 | MW 2000 | MW 3000 |

| MW 5000 | MW 7000 | MW 10000 | MW 20000 | MW 20000-30000 |

| MW 30000-40000 | MW 40000-60000 | MW 70000 | MW 100000 | MW 270000 |

| MW600000-1000000 | MW 750000 | MW 2000000 | ||

| POLYETHYLENEIMINE CAS 9002-98-6 of MW3000 | |

| ITEM | STANDARD LIMITS |

| Appearance | Colorless or pale yellow liquid |

| Assay | 30% |

| Specific gravity(25℃ g/cm3) | d425=1.0385 |

| PH | 10-12 |

| Refractive index | 1.3785 |

| Kinematic viscosity | 30-80 |

| Molecular weight | 3000-3500 |

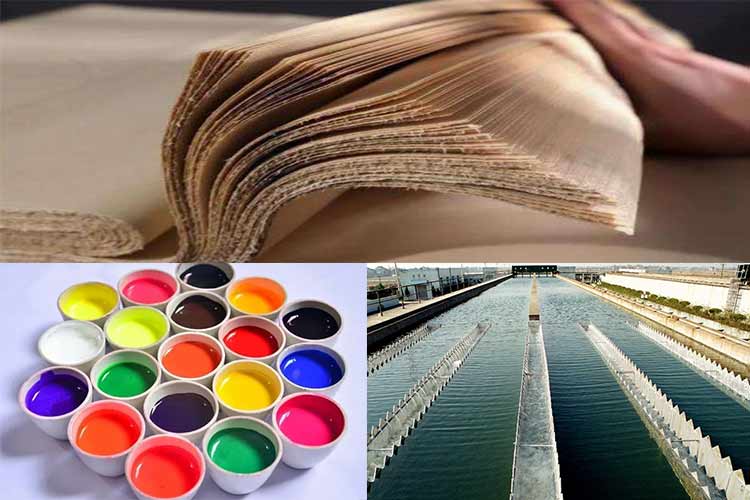

1. Used as wet strength agent of non sizing breathable paper, retention agent and beating agent in the process of papermaking, which can reduce the beating degree of pulp. Improve the dewatering capacity of paper. The dryness of the paper is increased by 1% – 4%. The production capacity is increased by 5% – 20%.

2. Widely used in the fields of printing ink, coating, adhesive and so on.

3. Used in papermaking water treatment, electroplating solution and dispersant.

4. Used as epoxy resin reagent, aldehyde adsorbent and dye fixative.

Packed it in 25kgs drum and keep it away from light at a temperature below 25℃.

Polyethyleneimine,branched,M.W.1800,99%; Polyethyleneimine,branched,M.W.70,000,30%w/vaq.soln.; Polyethyleneimine, approx. M.W. 60,000, 50 wt% aq. solution, branched; Polyethyleneimine, linear, M.W. 25,000; Polyethyleneimine (30% in Water); Ethylene iMine polyM; PolyethyleneiMine on silica beads, anion exchange resin, 20-40 Mesh; PolyethyleneiMine on silica beads, anion exchange resin, 40-200 Mesh; PolyethyleneiMine on silica beads, anion exchange resin, benzylated, 20-40 Mesh; PolyethyleniMine, Branched, Av. Mn (by GPC) Approx. 10,000; Poly(ethyleneiMine) solution ~50% in H2O; Poly(ethyleneiMine) solution average Mn ~1,200, average Mw ~1300 by LS, 50 wt. % in H2O; Poly(ethyleneiMine) solution average Mn ~1,800 by GPC, average Mw ~2,000 by LS, 50 wt. % in H2O; Poly(ethyleneiMine) solution average Mn ~60,000 by GPC, average Mw ~750,000 by LS, 50 wt. % in H2O; PolyethyleniMine, branched average Mw ~25,000 by LS, average Mn ~10,000 by GPC, branched; Polyethylenimine, linear; Polyethylenimine hydrochloride linear, average Mn 20,000, PDI <=1.2; Polyethylenimine hydrochloride linear, average Mn 4,000, PDI <=1.1; Polyethylenimine, linear average Mn 10,000, PDI <=1.2; Polyethylenimine, linear average Mn 5,000, PDI <1.2; PolyethyleneiMine on silica beads, anion exchange resin, benzylated, 40-200 Mesh; PolyethyleniMine, linear average Mn 2,500, PDI <1.2; polyethylenimine(35,000); polyethylenimine(40,000); Ethylene imine polymer solution; Ethyleneimine polymer solution; Ethyleneimine resin (50%); polyethylenimine 50% (W/V) aqueous*solution; PEI-7; PEI-15; PEI-30; PEI-45; PEI-250; PEI-275; PEI-700; PEI-1000; PEI-1400; Polyethyleneimine, branched, M.W. 50,000 – 100,000, 30% w/w aq. soln.; Polyethyleneimine; Polyethyleneimine (ca. 30% in Water) [for Biochemical Research]; Polyethyleneimine (ca. 30% in Water)Quality First,and Customer Supreme is our guideline to provide the best service to our customers.Nowadays, we are trying our best to become one of the best exporters in our field to meet customers more need for OEM/ODM Factory Zinc Plating Polyethyleneimine G-35 Sp-200 Sp-1050 P-1050 P-1000 Sp-018 CAS 68130-97-2, We adhere to the tenet of “Services of Standardization, to Meet Customers’ Demands”.

OEM/ODM Factory China Polyethyleneimine and Zinc Plating Polyethyleneimine, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our products and solutions. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best in your case always.