What Is Polyvinylpyrrolidone (PVP)?

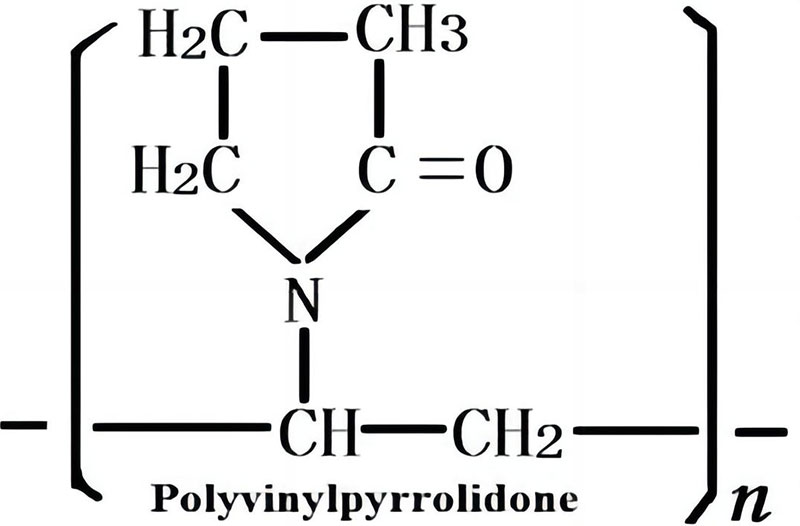

Polyvinylpyrrolidone, abbreviated as PVP. Polyvinylpyrrolidone (PVP) is a non-ionic polymer compound produced by the polymerization of N-vinylpyrrolidone (NVP) under certain conditions. It is used as an adjuvant, additive, and excipient in multiple fields such as medicine, textile, chemical, beverage, and daily chemical. According to product requirements, PVP can be divided into four types: industrial grade, cosmetic grade, food grade, and pharmaceutical grade. Homopolymers, copolymers, and cross-linked polymer series products with relative molecular weights ranging from thousands to over one million have been widely used due to their excellent and unique properties.

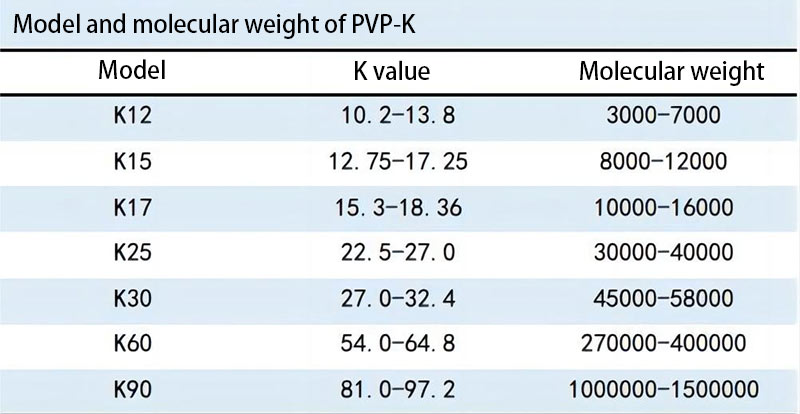

PVP is divided into four levels based on its average molecular weight, and is commonly represented by K values. Different K values represent the corresponding range of average molecular weight of PVP. The K value is actually a characteristic value related to the relative viscosity of PVP aqueous solution, and viscosity is a physical quantity related to the molecular weight of polymers. Therefore, the K value can be used to characterize the average molecular weight of PVP. Usually, the larger the K value, the higher its viscosity and stronger its adhesion. The main product varieties and specifications of PVP can be classified into viscosity levels of K-15, K17, K25, K-30, K60, and K-90 based on molecular weight.

UNILONG INDUSTRY can provide the following PVP-K series products:

| TYPE | PVP K12 | PVP K15 | PVP K17 | PVP K25 | PVP K30 | PVP K60 | PVP K90 | |

| Appearance | White powder | |||||||

| K Value | 10.2-13.8 | 12.75-17.25 | 15.3-18.36 | 22.5-27.0 | 27-32.4 | 54-64.8 | 81-97.2 | |

| NVP singel impurity (impurity A) |

(CP2005/USP26) %max | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| (USP31/EP6/BP2007) ppm max | 10 | 10 | 10 | 10 | 10 | 10 | 10 | |

| Water % max | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 | |

| Content % min | 95 | 95 | 95 | 95 | 95 | 95 | 95 | |

| pH (5% aqueous solution) | 3.0-5.0 | 3.0-5.0 | 3.0-5.0 | 3.0-5.0 | 3.0-5.0 | 4.0-7.0 | 4.0-7.0 | |

| Sulfate ash% max | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | |

| Nitrogen content﹪ | 11.5-12.8 | 11.5-12.8 | 11.5-12.8 | 11.5-12.8 | 11.5-12.8 | 11.5-12.8 | 11.5-12.8 | |

| 2-P content % max | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | |

| Aldehyde ppm max | 500 | 500 | 500 | 500 | 500 | 500 | 500 | |

| Heavy metal ppm max | 10 | 10 | 10 | 10 | 10 | 10 | 10 | |

| Hydrazine ppm max | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| Hydrogen peroxide ppm max | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

PVP, as a synthetic water-soluble polymer compound, has the general properties of water-soluble polymer compounds, including colloid protection, film-forming, bonding, moisture absorption, solubilization or coagulation. However, its most distinctive feature is its excellent solubility and physiological compatibility, which have attracted attention. In synthetic polymers, PVP, which is soluble in both water and most organic solvents, has low toxicity, and good physiological compatibility, is not commonly seen, especially in fields closely related to human health such as medicine, food, and cosmetics. The following is a specific introduction to its application areas:

In the field of daily cosmetics

In daily cosmetics, PVP and copolymer have good dispersibility and film-forming property. PVP can protect colloid in lotion, and can be used in fat and non fat creams, as setting liquid, hair spray and mousse setting agent, hair conditioner sunscreen, shampoo foam stabilizer, wave setting agent, and hair dye dispersant and affinity agent. Adding PVP to snow cream, sunscreen, and hair removal agents can enhance wetting and lubrication effects.

Washing field

PVP has anti fouling and re precipitation properties and can be used to prepare transparent liquids or heavy fouling detergents. Adding PVP to detergents has a good anti discoloration effect and can enhance cleaning ability. When washing fabrics, it can prevent synthetic detergents from irritating the skin, especially synthetic fibers. This performance is more outstanding than carboxymethyl cellulose (CMC) detergents. PVP can be compounded with borax as an effective ingredient in the formulation of phenolic disinfectant cleaning agents. The detergent composed of PVP and hydrogen peroxide has the functions of bleaching and killing bacteria.

Textile printing and dyeing

PVP has good affinity with many organic dyes and can combine with hydrophobic synthetic fibers such as polyacrylonitrile, esters, nylon, and fibrous materials to improve dyeing power and hydrophilicity. After PVP and nylon grafting copolymerization, the produced fabric improved its moisture resistance and moisture resistance.

Coatings and pigments

Paints and coatings coated with PVP are transparent without affecting their natural color, improving the gloss and dispersibility of coatings and pigments, enhancing thermal stability, and improving the dispersibility of inks and inks.

Medical field

PVP has excellent physiological inertness, does not participate in human metabolism, and has excellent biocompatibility, which does not cause any irritation to the skin, mucosa, eyes, etc. Medical grade PVP is one of the three major new pharmaceutical excipients advocated internationally, which can be used as a binder for tablets and granules, a co solvent for injections, and a flow aid for capsules; Detoxifiers, extenders, lubricants and film-forming agents for eye drops, dispersants for liquid formulations, stabilizers for enzymes and thermosensitive drugs, and can also be used as low-temperature preservatives. Used for contact lenses to increase their hydrophilicity and lubricity. In addition, PVP can also be used as a colorant and X-ray contrast agent; It can be used for various dosage forms of drugs such as tablets, granules, and water. It has detoxification, hemostasis, increased dissolution concentration, prevention of peritoneal adhesion, and promotion of erythrocyte sedimentation rate. PVP K30 has been officially launched with the approval of the national pharmaceutical regulatory department.

Food processing

PVP itself is not carcinogenic and has good food safety. It can form complexes with specific polyphenolic compounds (such as tannins) and is mainly used as a clarifying and stabilizing agent in food processing, such as beer, fruit juice, and wine. PVP can form complexes with specific polyphenolic compounds (such as tannins), which play a clarifying and anticoagulant role in fruit juice beverages. The application of cross-linked PVP in beer and tea beverages is particularly widespread. Polyphenolic substances in beer can bind with proteins in beer to form tannin macromolecular complexes, which seriously affect the flavor of beer and shorten its shelf life. Crosslinked polyvinylpyrrolidone (PVPP) can chelate with tannic acid and anthocyanins in beer, thereby clarifying the beer, improving its storage stability, and extending its shelf life. In tea beverages, the use of PVPP can appropriately reduce the content of tea polyphenols, and PVPP does not remain in tea beverages, making it reusable and greatly reducing costs.

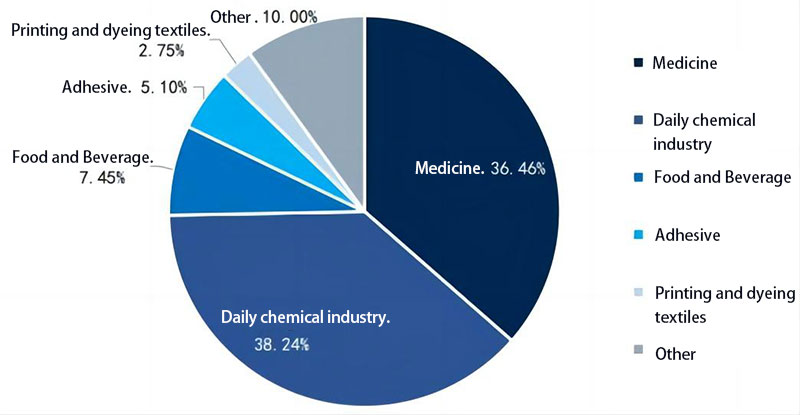

The main application areas of PVP are currently concentrated in the daily chemical and pharmaceutical industries, and the growth of these two industries will continue to drive the main demand for PVP consumption in the future. In the emerging field of PVP, in the lithium battery industry, PVP can be used as a dispersant for lithium battery electrodes and a processing aid for conductive materials; In the photovoltaic industry, PVP can be used as a dispersant to produce high-quality spherical silver powder for positive electrode silver paste, sheet-like silver powder for negative electrode silver paste, and nano silver particles. With the continuous improvement of lithium battery penetration rate and the increase of photovoltaic installed capacity, these two emerging fields will significantly drive the demand for PVP.

Unilong is a professional supplier, and the PVP series has been developed and produced for ten years. With the changes in the market, the supply of PVP products is in short supply. Currently, we have added two more production lines, with sufficient supply and favorable prices. Please feel free to inquire.

Post time: Dec-01-2023