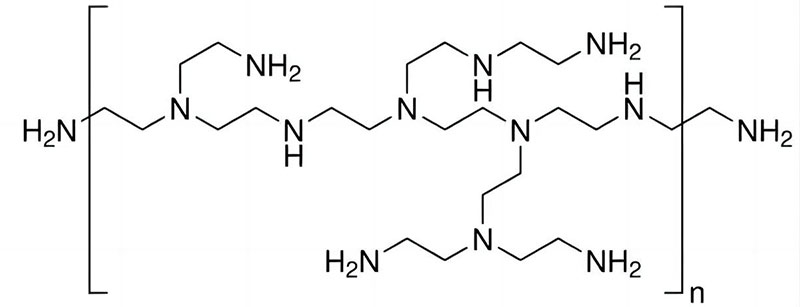

Polyethylenimine(PEI) is a water-soluble polymer. The concentration in water of commercial products is usually 20% to 50%. PEI is polymerized from ethylene imide monomer. It is a cationic polymer that usually appears as a colorless to yellowish liquid or solid with a variety of molecular weight and structural variants.

| Purity Optional | ||||

| MW 600 | MW 1200 | MW 1800 | MW 2000 | MW 3000 |

| MW 5000 | MW 7000 | MW 10000 | MW 20000 | MW 20000-30000 |

| MW 30000-40000 | MW 40000-60000 | MW 70000 | MW 100000 | MW 270000 |

| MW600000-1000000 | MW 750000 | MW 2000000 | ||

What is polyethyleneimine function?

1. High adhesion, high absorption amino group can react with hydroxyl group to form hydrogen bond, amine group can react with carboxyl group to form ionic bond, amine group can also react with carbon acyl group to form covalent bond. At the same time, due to its polar group (amine) and hydrophobic group (vinyl) structure, it can be combined with different substances. With these comprehensive binding forces, it can be widely used in the fields of sealing, ink, paint, binder and so on.

2. High-cationic polyvinyl imide exists in the form of polycation in water, which can neutralize and adsorb all anionic substances. It also chelates heavy metal ions. With its high cationic properties, it can be used in papermaking, water treatment, plating solution, dispersant and other fields.

3. Highly reactive polyethylenimine due to the highly reactive primary and secondary amines, so it can easily react with epoxy, acids, isocyanate compounds and acid gases. Using this property, it can be used as an epoxy reactant, an aldehyde adsorbent and a color fixing agent.

What is polyethylenimine used for?

Polyethylenimine (PEI) is a versatile polymer compound with a variety of uses, including but not limited to:

1. Water treatment and paper industry. As a wet strength agent, it is used in ungummed absorbent paper (such as filter paper, ink blotting paper, toilet paper, etc.), which can improve the wet strength of paper and reduce the damage of paper processing, while speeding up the water filtration of pulp and making fine fibers easy to flocculate.

2. Color fixing agent. It has a strong binding force for acid dyes and can be used as a fixing agent when acid dyes dye paper.

3. Fiber modification and dyeing auxiliaries. For fiber treatment, such as body armor, anti-cutting gloves, rope, etc.

4. Electronic materials. In the field of electronics, polyethylene imide film can be used as an isolating layer, insulating material and covering layer of electronic components, etc., with good insulation performance and high temperature resistance.

5. Food packaging. As a food packaging material, it has the advantages of moisture-proof, good gas resistance, non-toxic, tasteless, high temperature resistance, etc., and is widely used in the packaging of meat, poultry, fruits, vegetables, coffee and other products.

6. Medical materials. Polyvinylimine can be used in medical devices, diagnostic tools, medical packaging, etc., such as medical dressings and medical transparent films.

7. Adhesive. As a high-performance adhesive, it is used in the manufacture of aerospace, electronic components, automotive parts and so on.

8. Water treatment agents and dispersants. It is widely used in papermaking water treatment, electroplating solution, dispersant and other fields. Gene carrier. Polyvinylimide is a non-viral vector for gene delivery, especially suitable for co-transfection of multiple plasmids.

In addition, polyethylenimine also has the characteristics of high adhesion, high adsorption, high cation, high reactivity, etc., and it is also widely used in the fields of paint, ink, adhesive, fiber treatment, sewage treatment and so on.

In general, polyvinylimide is a versatile polymer with a wide range of applications, and its properties can be adjusted and optimized by changing molecular weight, structure and functionalization.

Post time: Mar-18-2024